Ceramic Spark Plug Manufacturing Process

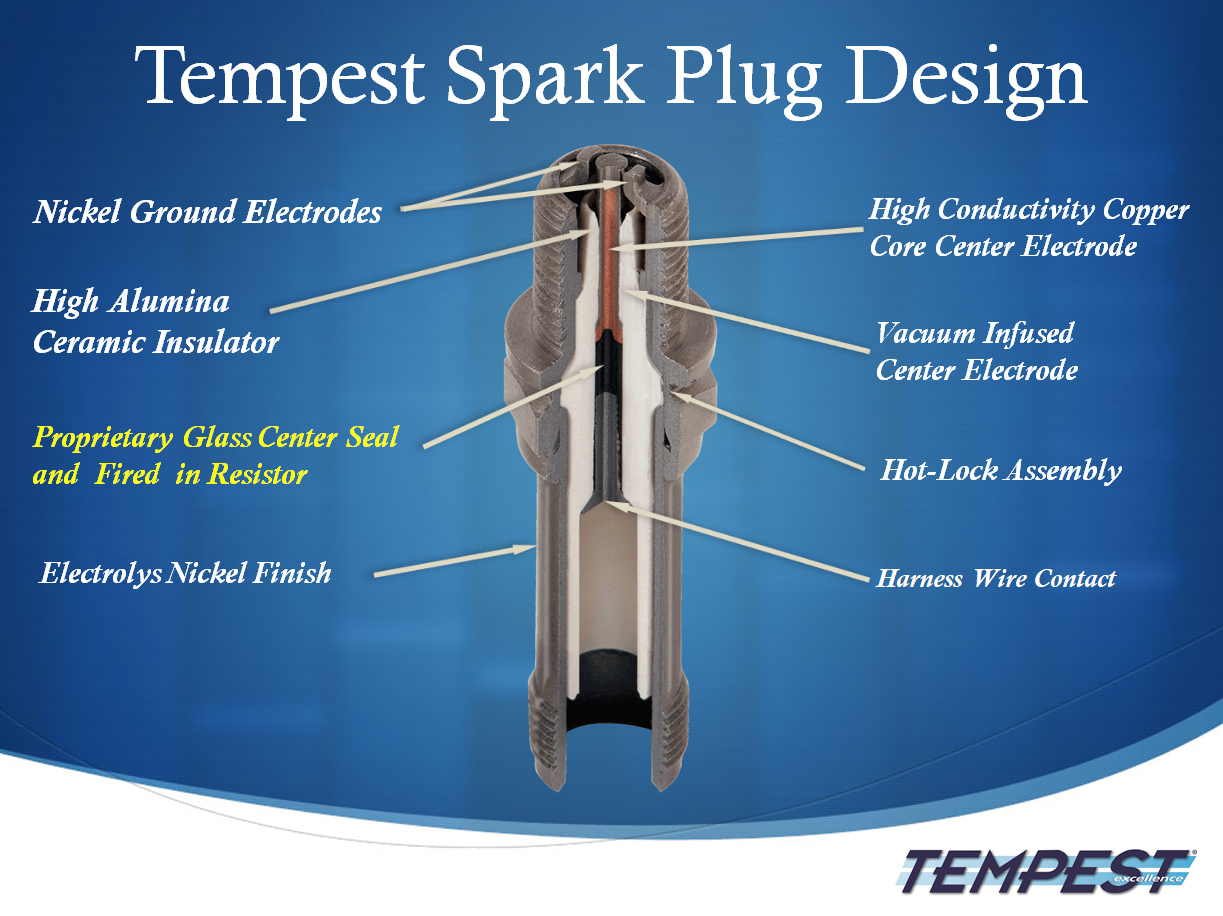

Specifically designed to reduce quenching.

Ceramic spark plug manufacturing process. Manufacturers test incoming parts and tools inspections and pressure testing ensure that. Known for durability and performance ngk manufactures oe spark plugs for inboard engines over 90 of outboard engines and almost 100 of personal water crafts. The ceramic insulator is the only barrier between the electrodes keller says in the release. The unprecedented level of ceramic performance we have achieved in surefire plus spark plugs enables a new generation of ignition systems that provide greater energy and.

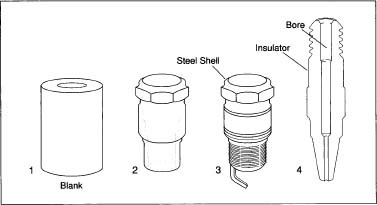

Ngk spark plugs provide better ignitability and quicker starts. Introducing suflicient powdered ceramic composition into a filling chamber to fill said chamber of a pressing tool comprising a stationary bottom ram having a pressing needle rigidly secured thereto and extending upwardly into said. A process for preparing a spark plug insulator blank by dry pressing a powdered ceramic composition mainly comprising metal oxides comprising the steps of. Based on our 25year production experience and good facilities we can supply the total solution from the development design of new products to manufacturing assembling for diverse requirements.

The process used to form ceramic materials is a heat treatment of very fine powders of the raw materials called sintering. Shengda ceramic is located in yixing china with an area of 4 000 square meters and fixed assets of over 1 million us dollars. Manufacturers implement quality control standards and practices throughout the process to ensure accuracy and safe manufacturing so that spark plugs can fulfil their function. The present invention relates to a spark plug having a novel center discharge electrode and a manufacturing process thereof.

Each major spark plug component is manufactured in a continuous line assembly process. A spark plug is a tool for delivering electric current from an ignition system to the flaming chamber of a spark ignition engine to light the compressed fuel or read more ceramic components buying guide 2020. Works with you on any product you need from prototype development to resolving any issue. Ngk is the world s largest oe supplier and manufacturer of spark plugs.

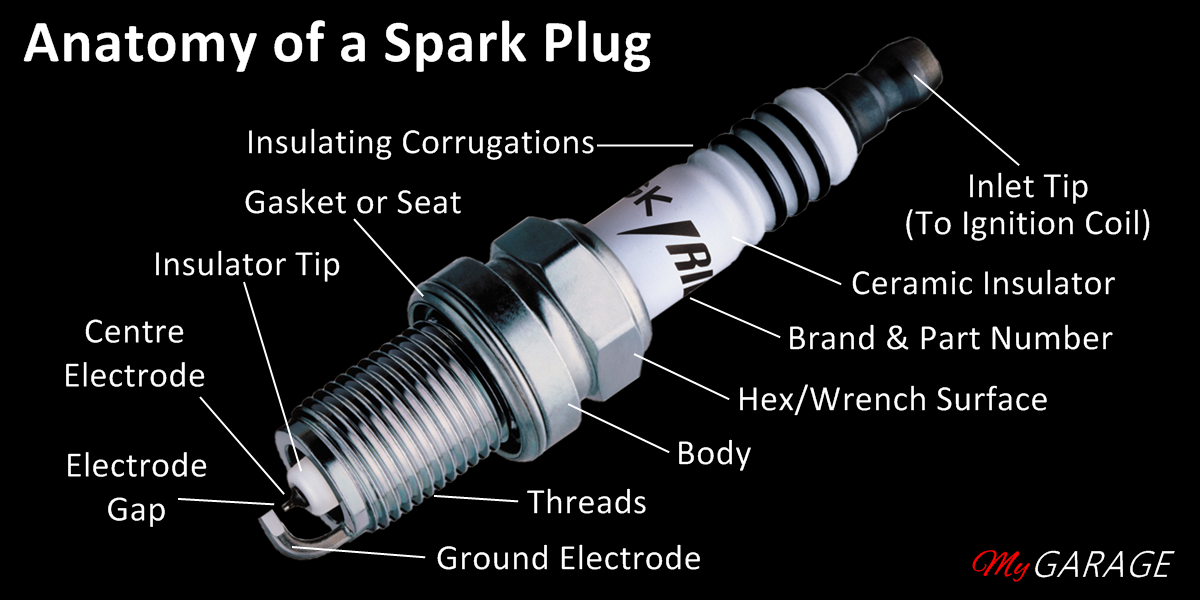

The energy to melt and cast ceramic raw materials would be far too costly. The electrodes in a spark plug typically consist of high nickel alloys while the insulator is generally made of aluminum oxide ceramic and the shell is made of steel wire. Established in 1995 shengda ceramic employs 70 employees. In the former type a.

With over 35 years of ceramic production experience alumina ceramic components inc. It forces the spark to jump the gap which initiates combustion. Ceramic materials ceramic materials cannot be formed by the manufacturing processes known from metallic or organic materials.